Products/Applications

The reactor agitator is a key component in reaction equipment, enabling material mixing through the rotation of a stainless steel shaft. Over time, the shaft experiences wear, leading to dimensional loss that disrupts operations. Given the shaft’s length (up to 5.2 meters) and the long production time for replacements, manufacturing new parts is costly and causes significant downtime.

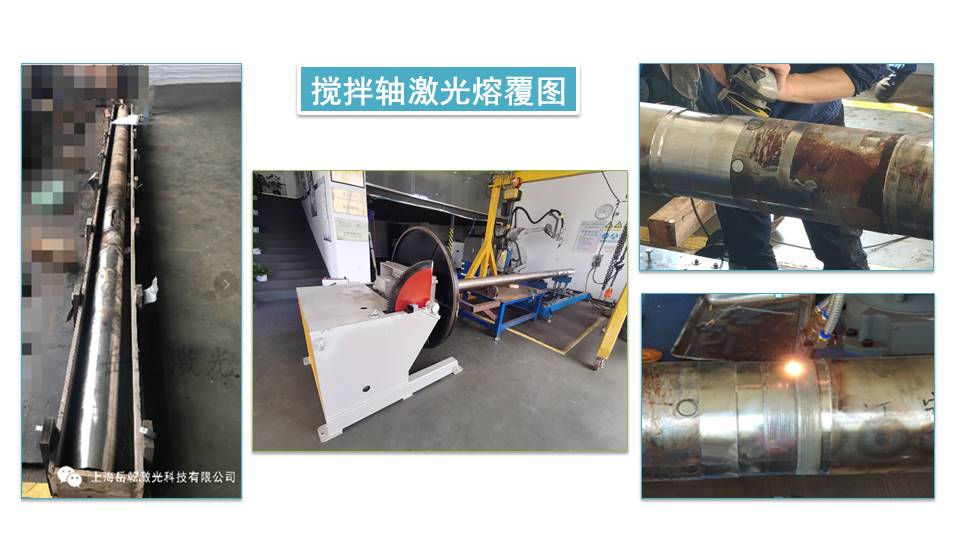

A chemical plant recently faced severe wear on its agitator shaft, resulting in downtime. After consulting our team, we repaired it using laser cladding additive re-manufacturing.

By applying multi-layer laser cladding with stainless steel alloy powders, we fully restored the shaft’s dimensions and completed the process within four days.

The cladding produced a dense bond with the substrate, significantly improving wear resistance. This solution cost less than one-tenth of a new part, met the customer’s wear and corrosion resistance needs, and minimized downtime, achieving efficient and sustainable re-manufacturing.

Laser cladding is ideal for shaft repairs, restoring dimensions while enhancing wear, corrosion, and impact resistance, far outperforming traditional electroplating methods.